Welding is one of the most important manufacturing processes in industrial production. In recent years, industrial robot technology has developed rapidly and its application in welding is increasing day by day. The main factor of welding robot performance is positioning accuracy. For robots with off-line programming, the control of absolute positioning accuracy is very important because of the deviation between simulation environment and real environment. Generally speaking, the absolute positioning accuracy of off-line programming robot is very low, and some even reach the order of centimeter error, so corresponding calibration is needed to improve its accuracy before normal operation.

Ontology calibration of off-line programming robot is divided into four steps: kinematics modeling, data measurement, parameter identification and error compensation. In the process of measuring robot attitude data, the choice of measuring equipment is very important, and the accuracy of the measurement results will be directly affected by the difference of accuracy and using conditions. Although the three-coordinate measuring instrument and theodolite have high precision, they can only be used for static measurement, and the measuring methods of club instrument and laser tracker are too cumbersome.

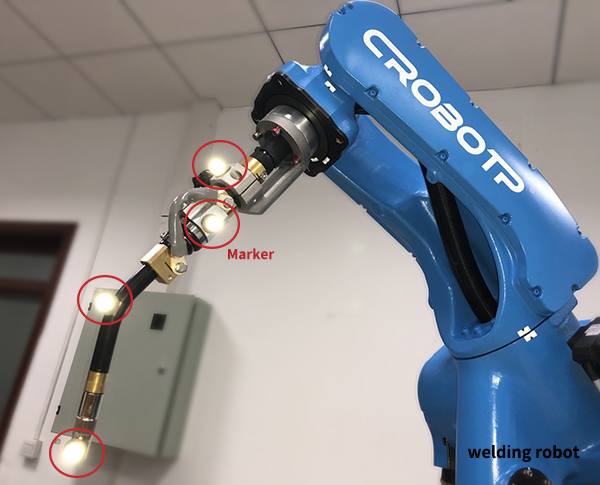

Therefore, the School of Electrical Engineering of Sichuan University adopted NOKOV optical motion capture system to collect the end pose data of welding robot. Optical motion capture technology has the advantages of high positioning accuracy, large working space and no need of contact measurement. After obtaining the data measurement values of the end pose and motion track information of the robot arm, the parameters of the robot kinematics model can be identified, and the nominal linkage parameters in the robot controller can be modified to realize error compensation and complete the ontology calibration.

In addition, the motion capture system can be used to verify the repeatability of other calibration schemes. Several groups of points are randomly selected in the workspace of the robot, and the angle values of each joint of the robot are obtained by inverse kinematics solution. The actual position of the robot end is measured by NOKOV optical motion capture system, and the maximum, average and root mean square values of position errors of these points are taken as evaluation indexes to evaluate the effect of calibration algorithm on improving the absolute positioning accuracy of the welding robot.

At present, the college has established a standard and efficient robot calibration process based on motion capture system, which makes the practical application of welding robot easier.