Robots have many important industrial applications and also play a large role in our daily lives. As the tasks required of robots develop in complexity, the precision requirements of such robots also increase. In evaluating the performance of a robot, absolute accuracy is among the most important measurements.

A high-precision calibration is required to improve the absolute accuracy of such robots. The calibration process may be divided into three stages. The first stage calibrates the drivers and joint sensors such that a relationship between the data from the joint displacement sensor and the actual joint displacement is derived. The second stage incorporates the calibration of the robot’s geometric parameters, targeting the motion error and the pose error caused by the structural parameter errors of each connecting rod. The third and final stage is a non-geometric calibration, targeting errors caused by factors including joint flexibility, friction, clearance, and connecting rod flexibility.

Measurement of parameters such as joint displacement and pose parameters is an important step preceding parameter identification and correction in the calibration process. Pose measurement may be conducted through two methods: contact and non-contact. Contact measurement severely limits the pose range of the robot. Non-contact measurement requires a complicated and time-consuming process that also faces several hardware shortcoming, such as the size limitations of coordinate-measuring machines and the environmental sensitivity of laser trackers.

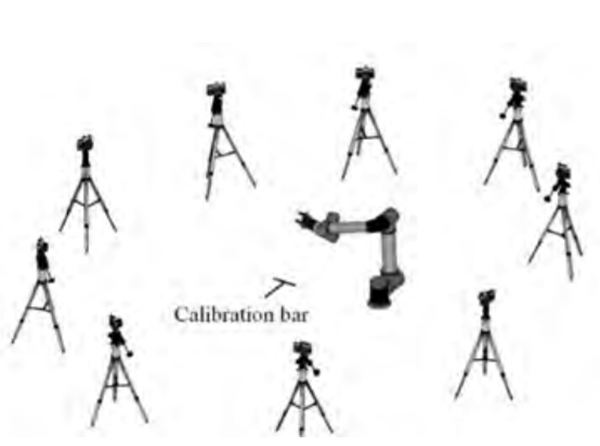

Researchers from the School of Aerospace Engineering and Applied Mechanics of Tongji University proposed a visual measurement method for multi-point dynamic capture. A system of NOKOV motion capture cameras are arranged around the robot. By tracking the multiple reflective markers attached on each joint of the robot, the changes in each joint’s position and orientation may be measured.

The data collected by the NOKOV motion capture system is then used in Rodrigues’ rotation formula to determine the absolute joint displacement. Using a kinematic model of the robot and a coordinate system transformation, a parameter calibration may be completed with a small amount of error. With this method, joint displacement and geometric parameters of the robot may be calibrated simultaneously through a single experiment.

The positioning accuracy of the NOKOV motion capture system can reach the sub-millimeter level, which can meet the needs of high-precision multi-point measurement.

Bibliography: