Position detection of cantilever road headers is the foundation of automation of the mechanical working face. By reliably collecting the real-time position of the road header, we can intelligently automate the mechanical working face.

To improve the production efficiency of the underground excavation face, a research team at the School of Mechanical and Electrical Engineering at Xidian University proposed a cantilever road header position and posture detection system based on machine vision and inclination sensors using an explosion-proof laser pointer for underground mining. A three-dimensional laser target is equipped to the road header, which allows for real-time positioning and posture detection without significant changes to the underground construction equipment. The validity and reliability of these methods were verified by a series of experiments.

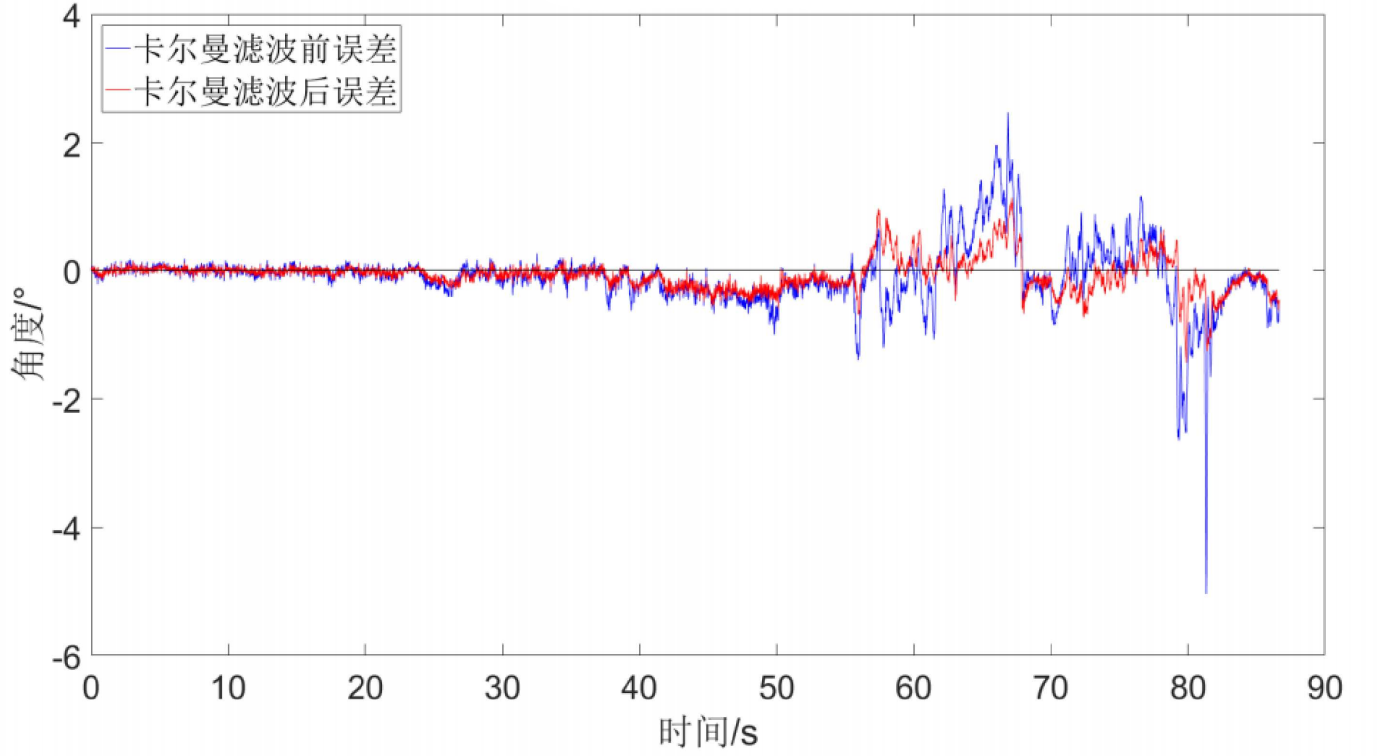

Inclination sensor data filtering experiment

The inclination sensor is one of two input sources of the posture detection system. The accuracy and stability of the real-time angle data collected directly affects the final output posture data.

In the experiment, the inclination data of the motion capture system measured by NOKOV was used as a benchmark to evaluate the inclination sensor data before and after filtering. The results show that the error in the angle of the inclination sensor before and after Kalman filtering is significantly reduced during movement, showing that this filtering is necessary and effective in the process of angle measurement.

Rotational angle error around Y-axis

Indoor experiment of posture detection system

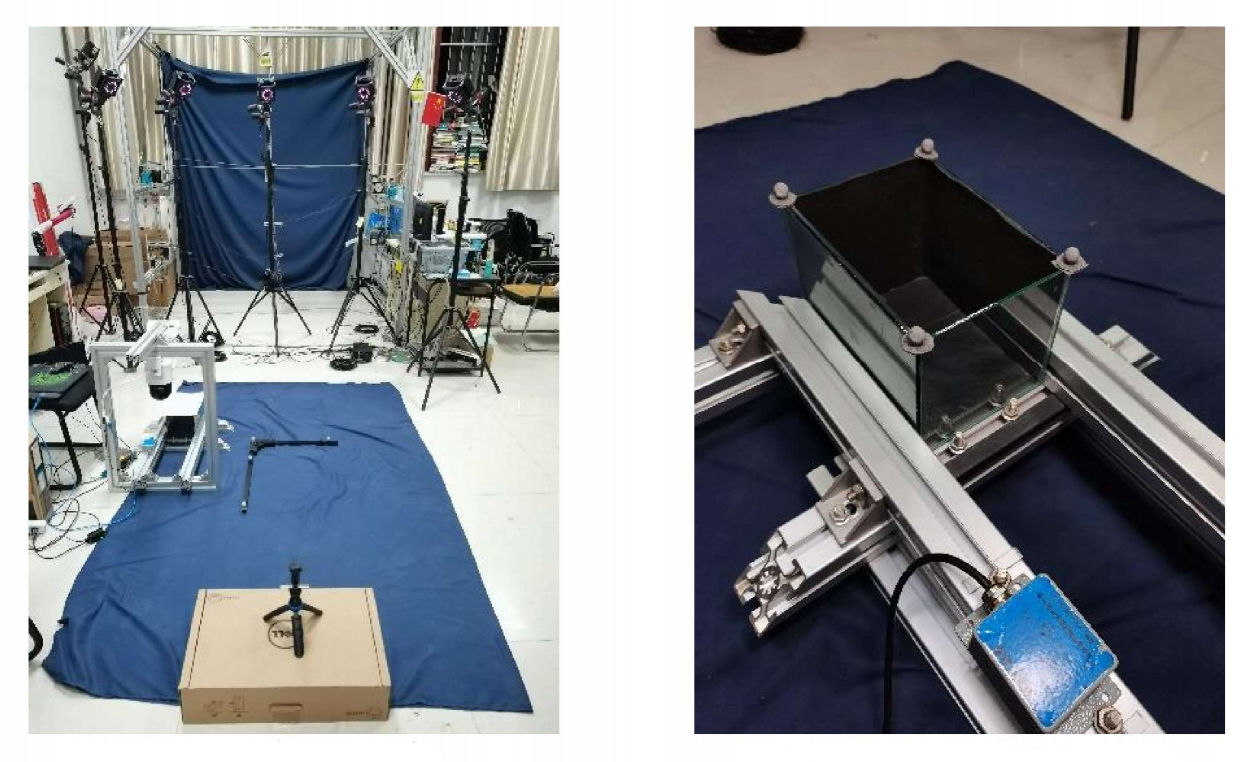

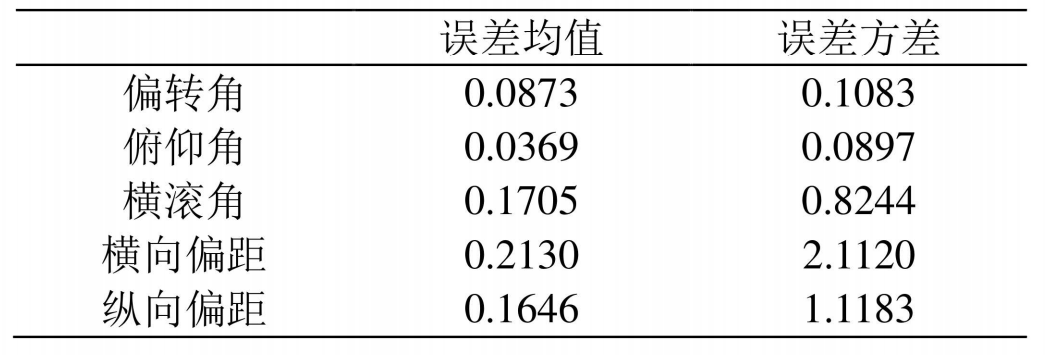

The main purpose of the research team designing the pose detection system is to detect, in real time, the five positional parameters of the cantilever road header relative to the axis of the roadway, including the deflection angle, pitch angle, roll angle, lateral offset and longitudinal offset. In the indoor experiment, the research team measured the posture parameters of the indoor prototype using the NOKOV metric motion capture system and global positioning systems as a benchmark for the laser target. Evaluation analysis was used to verify the accuracy of the posture detection system.

Calibration of the global coordinate system and layout of markers on laser target

Calibration of the global coordinate system and layout of markers on laser target

The experimental results show that the angle measurement error of the indoor experimental prototype equipped with the posture detection system is about 0.1° within a distance of 2 meters, and an offset measurement error of about 0.2 mm. Then, extrapolating the small model error of the indoor experimental prototype to an actual working environment, assuming that the offset measurement error and the irradiation distance have a linear relationship, the offset measurement error of the system within a distance of 200 meters is about 4.8 mm, which meets the measurement accuracy that practical scenarios require.

Bibliography:

张世雄. 基于机器视觉和倾角传感器的位姿检测系统及验证[D].西安电子科技大学,2021.DOI:10.27389/d.cnki.gxadu.2021.000178.