A research team composed of researchers from Northwest A&F University, North Minzu University, Guizhou University of Traditional Chinese Medicine, and Saken Seifullin Kazakh Agrotechnical University has done an interesting study on apple picking robots, “Design and evaluation of a robotic apple harvester using optimized picking patterns,” which was published in Computers and Electronics in Agriculture, a zone 2 SCI journal in Agricultural Sciences.

The research team utilized data collected from a motion capture system to construct a humanoid harvesting motion model, then conducted a comparative analysis of two types of motions applicable to apple harvesting robots: the optimized "horizontal pulling and bending" motion, and the humanoid motion. Comprehensive performance evaluations of the robotic system were carried out through on-site testing. This study provides an innovative approach to enhance the efficiency and performance of apple harvesting robots, laying the foundation for future application expansion scenarios.

I. Research Background:

To reduce the cost and risk of apple harvesting, mechanization in the industry is becoming increasingly necessary. With the development of machine vision technology, apple picking robots have become a popular area of research. These robots can perceive their environment and autonomously identify, harvest, and collect fruits, but are currently in experimental and trial stages. The selection and optimization of harvesting motions plays a crucial role in the overall performance and efficiency of apple picking robots.

II. Experimental Process:

The mechanical hand is a critical hardware component for performing apple-picking actions. The design of the mechanical hand’s movement pattern is based on manual picking motion data and path planning. The research team used the NOKOV motion capture system to collect data on the upper-arm motion of apple pickers using eight digital cameras placed around the test area. Each camera has a 2048x1088 resolution and a 3D accuracy of ±0.15 mm. They collected data by tracking marker points, which was transmitted to the host machine for real-time processing to calculate the position, velocity, and acceleration of the moving objects in space (Figure 1).

Figure 1. Motion capture system

1.Collection of Humanoid Motion Data and Path Planning:

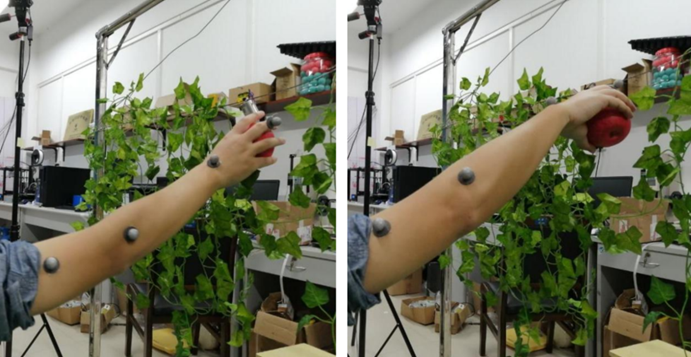

Fluorescent markers were attached on the picker's shoulder, elbow, wrist, and fingertips (Figure 2) in this experiment. Due to the structural differences between the mechanical hand and the human arm, only fingertip trajectory data was used for analysis.

Figure 2. Picking motion capture process

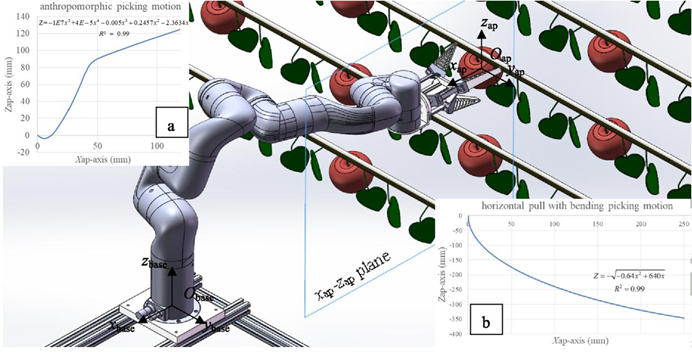

Because the picking motion involves short and quick movements, the data acquisition frequency was set to 100 frames per second. Simultaneously, to maintain high tracking accuracy, the system ensured that at least three cameras were tracking each marker point. The initial position of the fingertip marker at the start of motion was used as a reference and changes in vertical height were recorded every 5 mm of horizontal displacement. The data collection experiment was conducted 10 times. After the experiments were completed, polynomial fitting was applied to the averaged data, resulting in the fitted trajectory as shown in Figure 3 (a).

Figure 3. Trajectories of two types of picking movements: (a) anthropomorphic picking movements and (b) "bent horizontal pull" picking movements

2.“Horizontal Pulling and Bending” Motion Path Planning:

Path planning was performed using MoveIt, as shown in Figure 3 (b). After the mechanical hand grasped the fruit, the picking trajectory started from the fruit’s position in the x-y plane.

III. Experimental Results:

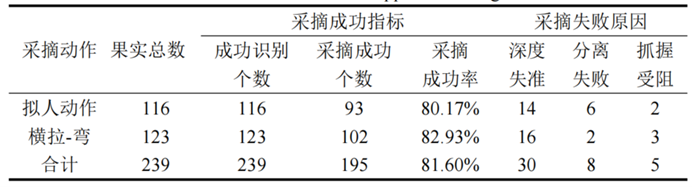

A statistical summary of the apple harvesting field evaluation is shown in Table 1. The apple picking success rate using the humanoid picking mode was 80.17%, which was 2.76% lower than when using the “horizontal pulling and bending” action (82.93%). Furthermore, in terms of time, the cycle time for the picking process using the “horizontal pulling and bending” motion was 12.53±0.53 seconds, which is 4.64 seconds less than the average time using humanoid picking motion (17.17±0.36 seconds). The picking operation itself took 1.14 seconds and 3.13 seconds, accounting for 9.10% and 18.23% of its total cycle time, respectively.

Table 1. Statistical summary of apple harvest test results

The experimental results show that both picking movements have potential for application in picking robots. Compared to humanoid motion, the “horizontal pulling and bending” picking movement has superior picking cycle times and success rates. Enhancing the robot's ability to perceive its environment and pick apples growing on long, pendulous branches are two potential research directions. In the future, humanoid motion may find applications in harvesting robots operating in unstructured orchards.

Bibliography: