As China’s agricultural industrialization progresses, fruit cultivation plays an increasingly important role in the farming industry. In contrast to traditional food crops such as wheat and corn that have been fully automated with regards to planting and harvesting, fruits that are easily damaged including apples and pears still need to be picked manually. This greatly increases labor costs while harvesting operations also retain high risks. Thus, the development of mechanically automated apple harvesting robots has an important practical application.

Apple harvesting robots are composed primarily of two parts: a detection system and a robotic arm, incorporating technology such as machine vision, image processing, robotic kinematics, and multi-sensor fusion. While researchers have developed several apple-harvesting robots, there are still many arear in which these robots have room for improvement. Such areas include the assessment of fruit damage, the improvement of the robot’s visual fruit detection model, and the development of a mechanism to reliably separate fruit.

Attempting to reduce damage to apples as they are picked, researchers at Northwest A&F University tested and optimized the picking mechanism of apple harvesting robots. The researchers first created a model of the branches, stalks, and fruits encountered by the apple-picking robot. They compared the results from their simulation with real-world experimental data to establish a theoretical basis for the optimal robotic mechanism and a damage assessment system.

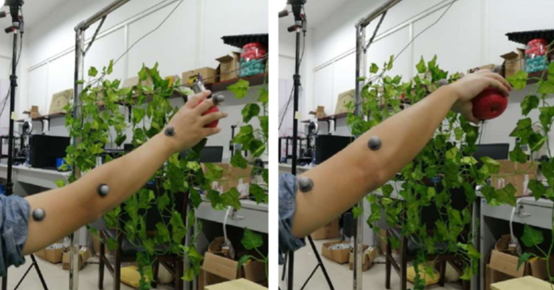

As the picking motion of the robotic arm directly affects any possible damage to the fruit itself, the researchers attempted to emulate the movements of human fruit picking through the robotic arm. Using a NOKOV motion capture system to track the motion of the upper arm of a human manually picking fruit, they then directed the robotic arm to make the same movements.

8 NOKOV motion capture cameras were arranged around the testing site, while reflective markers were attached to the shoulder, elbow, wrist, and fingertip of the human tester. The NOKOV motion capture system was used to collect the trajectory of each joint of the human tester’s arm, whereas only the fingertip trajectory data was analyzed to plan the final trajectory of the robotic arm.

Bibliography: