Exterior view of Nomadic Wood (looking) installation

Light as a frightened bird, graceful as a swimming dragon. This art exhibit, titled "Nomadic Wood (looking)" is soft and soothing to the eye. Each piece of curved wood was created by Yuan Feng of Tongji University’s construction robot team, which specializes in wooden structure assembly.

Click on the following video to follow Professor Yuan Feng and experience the birth of "Nomadic Wood (looking)"

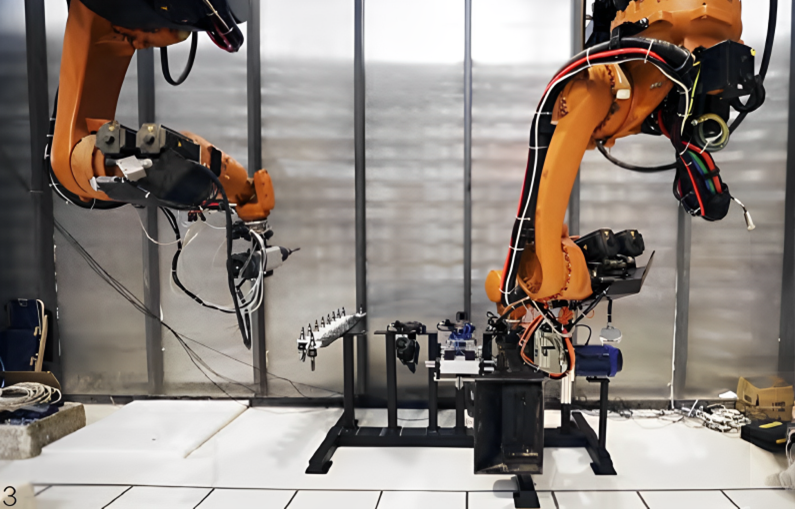

Robotic workbench tool arm

Current developments into robotic construction platforms domestically and abroad simplifies a typical system into four main parts: a robot construction equipment platform, a material processing system, a perception system, and a control system.

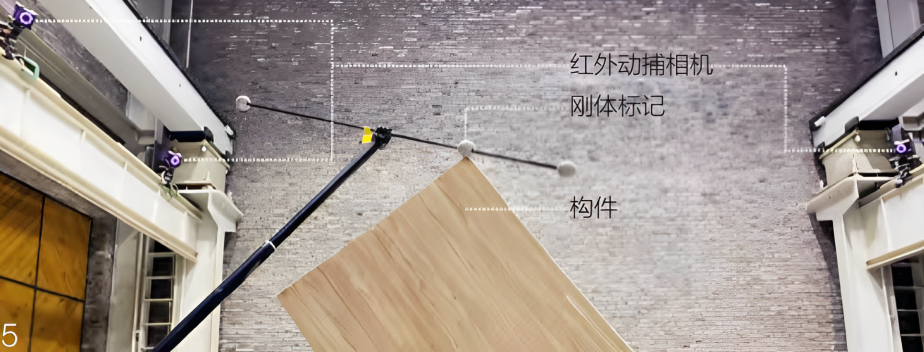

Robotic construction platform in motion

The perception subsystem implements sensors to detect the current state of machinery and the operating environment, improving the abilities of the robotic platform to build complex structures. Additionally, real-time monitoring of materials, tools and construction progress can significantly improve work efficiency.

The research team decided on the NOKOV motion capture system as the core sensor of the platform’s perception system and evenly distributed 12 Mars 2H infrared cameras around the robot’s operating environment. These cameras recorded the position of reflective markers positioned on the robot. This data was then used to perform data processing, system calibration, rigid body creation, and other tasks through the motion analysis computer software.

At the same time, the recorded motion capture data was imported into Grasshopper software through a custom data interface to obtain the positions of the markers and rigid bodies for visualization.

Motion capture system configuration

NOKOV motion capture systems can guarantee micron-level measurement accuracy and provide the accurate real values required in experiments. As such, NOKOV systems are implemented in robotic assembly systems as the core perception sensor, allowing the system to solve the spatial positioning problems of complex parts in wooden structure construction.

The operating arm of a digital intelligent robot platform equipped with a perception system

The success of Professor Yuan Feng’s "Nomadic Wood (looking)" has shown more people that robotic construction platforms have a great potential to adapt to the changing needs of design and construction systems.

It is believed that in the near future, with the development of the robotic prefabricated construction industry driven by mass customization, construction design will allow for much more individualism and diversity.To make this happen, motion capture will also play a growing role in the advancing research of such robotic platforms.

Bibliography: