Throughout China’s thousand-year history of liquor production, the traditional brewing process has been continuously refined. The device used in this process is known as a retort and was originally developed as a steaming tool. During the retort distillation process, raw materials are evenly spread into the retort pot layer by layer, ensuring an even flow of steam from the bottom to the top. The alcohol is then distilled out of the retort and collected.

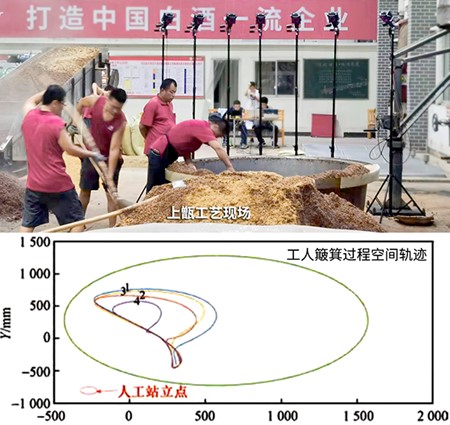

Fig. 1 caldron process

As the main step in liquor production, the retort process directly determines the yield and quality of the liquor produced. Currently, in most breweries, the retort process still requires significant manual labor. During this time, which typically takes between 35 and 40 minutes, workers have to repeat shoveling and spreading actions hundreds of thousands of times, handling a total mass of materials exceeding two tons.

Fig. 2 The generalization results of the artificial caldron-feeding trajectories

The emergence of high-precision and high-load industrial robots has made it possible for industrial robots to replace manual labor in the distillation process. Existing robots perform actions following predetermined commands which are designed to evenly layer the raw material into the retort. However, in some cases, this task becomes difficult due to limitations in the robot's range of motion.

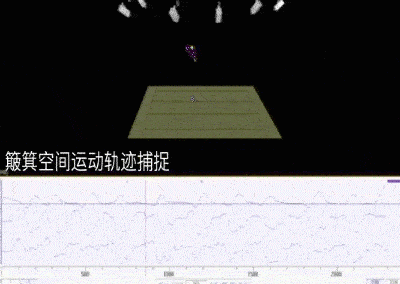

Fig.3The Nokov infrared motion capture system

In order to emulate the manual distillation process as closely as possible, researchers from the Shanghai Jiaotong University designed a robotic system for the distillation process after analyzing manual distillation operations. The researchers arranged 6 NOKOV optical motion capture cameras at the distillation site, attached three reflective markers to the dustpan, and recorded the motion and trajectory of the dustpan using these markers.

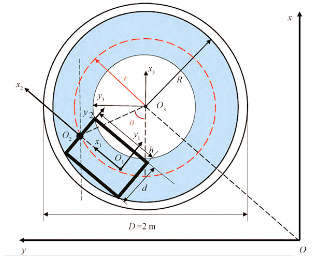

Figure 4 Top view of the workspace

Because manual labor is unable to achieve perfect consistency while spreading retort materials, the researchers proposed a generalized algorithm for the caldron feeding trajectory based on B-spline curve Gaussian model.The information collected by the NOKOV motion capture system is imported into this generalized model to obtain the trajectory of the dustpan during the distillation process.

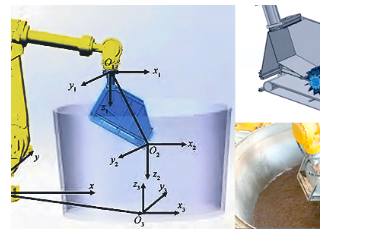

Figure 5 distillation robot working in real life

After a generalization was established, the researchers partitioned the working area, calculated the necessary trajectory of panning for each area, and designed a robotic retort system. This system uses a six-directional industrial articulated arm and is equipped with an end hopper mechanism that can control the flow rate of the caldron feeding.

Figure 6 3D view of the distillation robot workspace

By calculating the maximum speed in each area and the performance of the servomotor in the hopper mechanism, the researchers established an autonomous retort operation that closely mimicked the results of manual labor.

Bibliography:

[1] Yang Yi,Wang Hongbin,Zhang Liyin,et al.Robot operation systemfor caldron feeding in traditional distillation of Chinese liquor[J]. Science Technology and Engineering,2021,21( 36) : 15516-15528.