Rigid robotic arms already have many industrial applications but encounter difficulties when operating in restrictive or otherwise complex environments. Bionic continuum robots, modeled after living organisms such as snakes, elephant trunks, and octopus tentacles, aim to solve this problem. Continuum robots are composed of continuous joints, granting them greater flexibility than traditional robots and allowing them to perform better in complex environments. In recent years, continuum robots have been adopted for medical and detective applications.

Like rigid robotic arms, continuum robots require a kinematic model for precise user control. A joint research team from Sichuan University and the Electric Power Research Institute of State Grid Ningxia Electric Power Co., Ltd. proposed a universal method for a complete kinematic model of single-segment and multi-segment continuum robots based on the wire-driven continuum robot. This model assists with the difficult process of inversely mapping the working space to the driving space of the robot.

The researchers proposed a complete kinematic research methodology by applying a particle swarm algorithm to the segments of constant curvature. Taking a double-segment continuum robot as an example, the proposed kinematic model may derive the necessary robotic adjustments with inverse kinematics after a position in the working space is targeted, then direct the double-segment continuum robot to that targeted position.

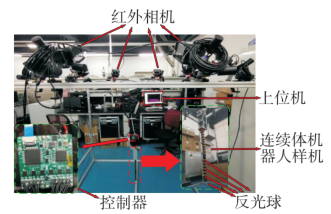

The researchers also designed and tested a physical prototype inside an experimental environment to verify the kinematic model of the continuum robot outside of simulations. The experimental environment included a double-segment continuum robot prototype, an electronic control system, and a NOKOV optical motion capture system.

In the experiment, the particle swarm algorithm was used to derive the necessary joint adjustment of the continuum robot given any target point position in the workspace. These adjustments were then mapped to the robot’s driving space and performed by the driving wire. A total of seven reflective markers were attached to the robot, with three at the beginning, middle, and end of each of the two segments, and a final marker at the very end of the continuum robot. Eight NOKOV motion capture cameras were used to collect and track the positions of the segments and the shape of the robotic arm.

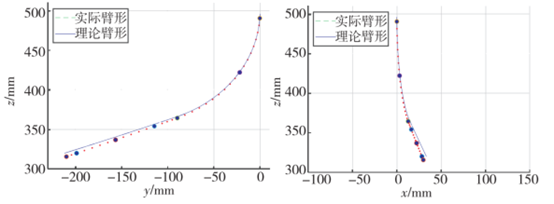

To evaluate the movement precision of the double-segment continuum robot, the NOKOV motion capture system collected the positions of the reflective markers placed at the beginning, middle, and end of each robotic segment. The corresponding curve of each segment was then derived by plotting these positions in three-dimensional space; the two segments were then combined to obtain the curvature of the entire robot. Because the NOKOV motion capture system can achieve sub-millimeter accuracy, the researchers were able to accurately compare the actual shape of the continuum robot with that of the kinematic model. From this analysis it may be concluded that the proposed complete kinematic model for continuum robots is both fast and accurate.

Bibliography: