The absolute accuracy of industrial robots is an important indicator for evaluating their overall performance. The accuracy of robots may be affected by factors such as machining errors, assembly errors, component wear, end-effector load variations, and changes in temperature. This is particularly disadvantageous in certain applications including high-precision satellite assembly and aircraft assembly. With the continued development and usage of industrial robots, the demand for accuracy is increasing. As such, improving the absolute accuracy of industry robots is a significant issue that needs to be addressed.

Research from the School of Aerospace Engineering and Mechanics at Tongji University have proposed a new calibration method to improve the absolute accuracy of industrial robots using a combination of motion capture systems and Extreme Learning Machine (ELM), and artificial neural network. The proposed method significantly improves robot pose accuracy compared to traditional calibration methods. This research provides a new approach to improving the performance and efficiency of industrial robots in various fields.

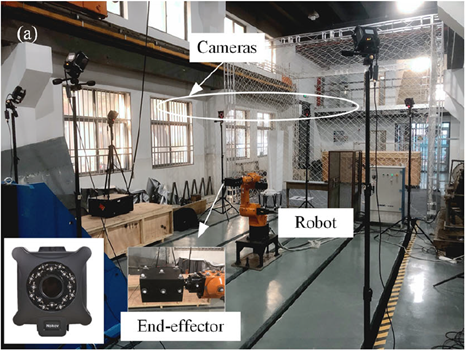

Validation Experiment

The industrial robot was placed in the geometric center of eight motion capture cameras. A hollow aluminum device was attached to the end effector with bolts. Then, fifteen reflective markers were attached to each joint of the robot and the end effector, totaling about ninety markers. During the experiment, 500 robot pose movements were randomly selected, and the NOKOV motion capture system was used to continuously capture the motion of the robot, collecting the position and orientation of each joint. This data was then used for DH parameter calibration. Finally, the calibration method was evaluated using the standard deviation of the error compared to traditional kinematic calibration methods.

Experimental robot and motion capture system

Experiment video

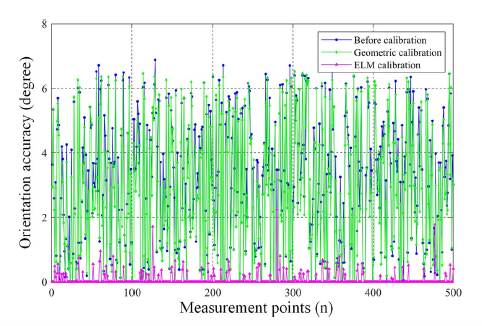

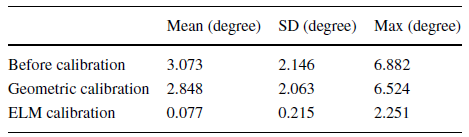

The experimental results show that with increasing sources of geometric and non-geometric errors, the positioning accuracy of the industrial robot improves from 3.073 degrees to 0.077 degrees under the improved calibration method. This confirms the effectiveness of the algorithm and validates the expected results.

Experimental positioning accuracy

Summary of positioning errors of the robot in the experiment

Bibliography: