1. Project Overview

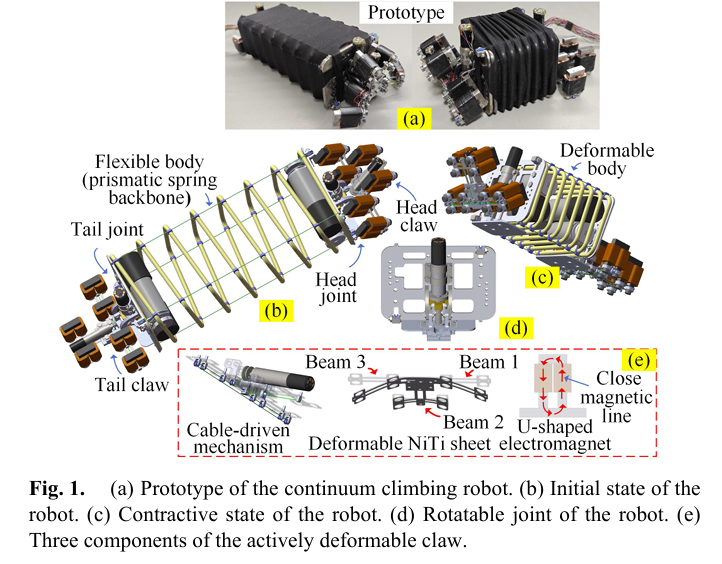

This article presents a continuum climbing robot designed for nuclear facility inspection, developed by the research team of Prof. Jianwen Zhao at Harbin Institute of Technology (Weihai). The robot features a retractable prismatic spring backbone. Kinetostatic models are developed and validated through finite element analysis and physical experiments using a NOKOV 3D motion capture system.

The continuum climbing robot is designed for inspection tasks in confined and discontinuous environments, such as pipelines, pressure vessels, and complex equipment surfaces found in nuclear facilities.

The robot features a retractable prismatic spring backbone, enabling continuous bending, axial extension, and stable crawling across curved and non-continuous surfaces.

Continuum robots move through continuous deformation of flexible backbones, making them suitable for inspection in confined and complex environments, such as pipelines and pressure vessels in nuclear facilities.

In nuclear inspection scenarios, robots must adapt to curved surfaces, narrow spaces, and discontinuous structures. Traditional rigid or wheeled robots face limitations in mobility and surface adaptability under these conditions.

Existing continuum robot models often rely on constant-curvature assumptions and circular backbone geometries, which reduce accuracy when gravity, external loads, or non-circular, retractable structures are involved. Moreover, many models cannot balance computational efficiency and prediction accuracy.

Therefore, general and efficient kinetostatic modeling methods for non-circular, retractable spring backbones are still lacking, limiting the practical deployment of continuum robots in nuclear inspection tasks.

3. Contributions of This Work

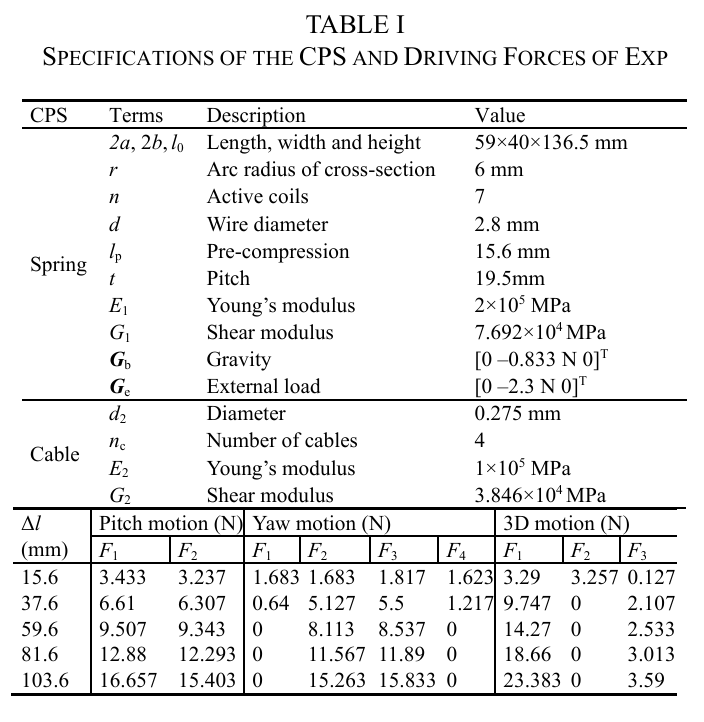

This work investigates a cable-driven retractable prismatic spring backbone for a continuum climbing robot operating in discontinuous inspection environments.

The main contributions are:

A retractable prismatic spring backbone capable of omnidirectional bending is proposed, enabling stable crawling and surface transitions in confined spaces.

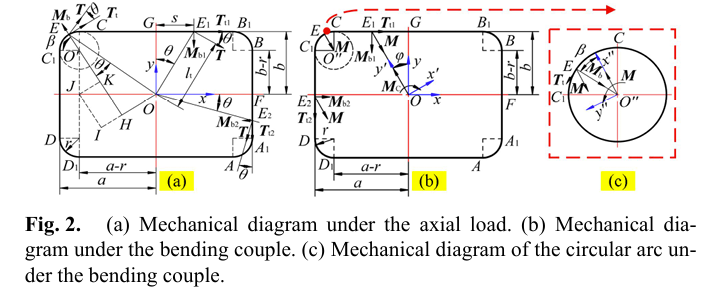

The non-circular spring backbone is equivalent to an elastic beam with anisotropic bending stiffness, derived using the projection principle of micro-segment deformation.

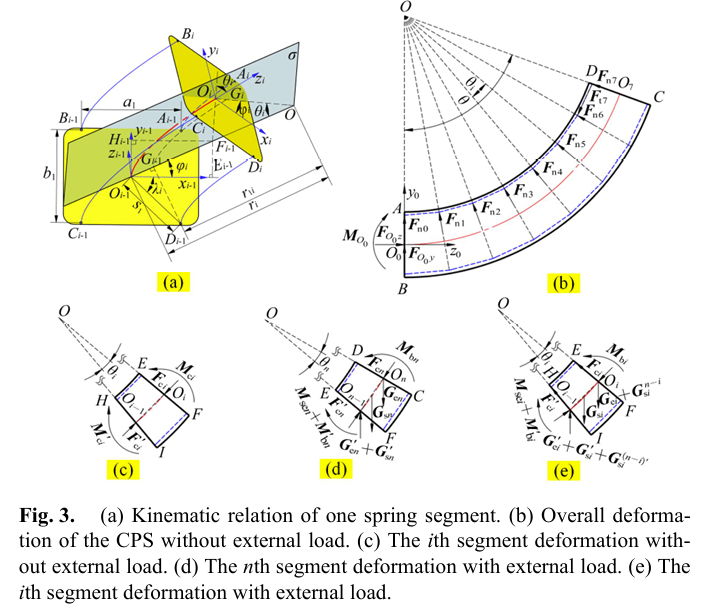

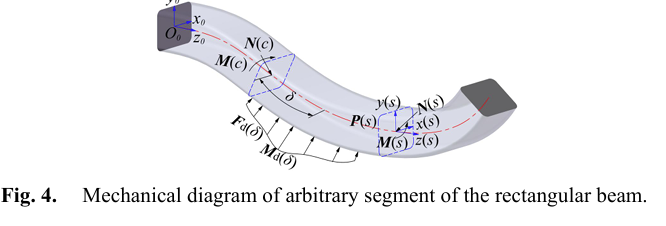

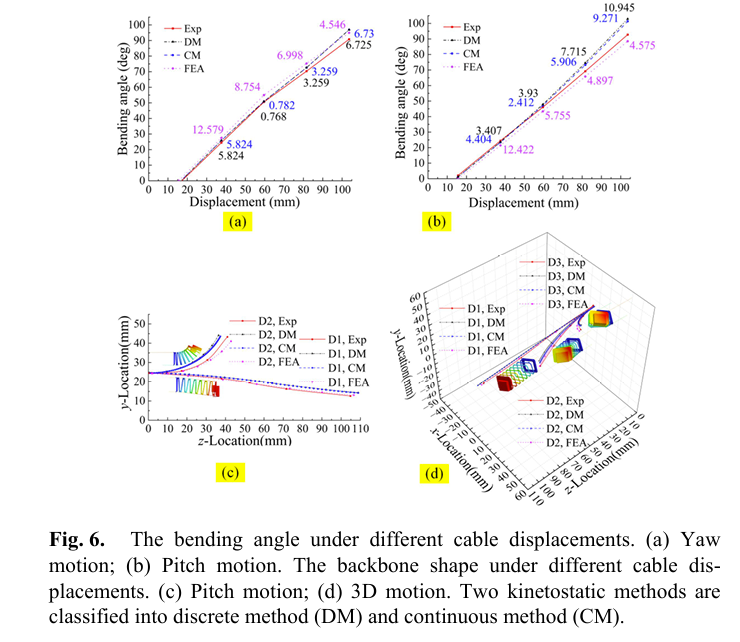

Two kinetostatic models are developed: a discrete finite-segment model (DM) for efficient computation, and a continuous Cosserat-rod-based model (CM) for higher shape prediction accuracy.

The proposed methods are validated through finite element analysis (FEA) and physical experiments.

To describe the deformation of the retractable prismatic spring backbone under cable forces, gravity, and external loads, the backbone is equivalent to an elastic beam with anisotropic bending stiffness.

Two complementary modeling approaches are developed:

Backbone discretized pitch by pitch

Compression and bending decoupled via linear superposition

Analytical expressions for bending and rotation

Suitable for fast computation and control applications

Based on an equivalent rectangular beam

Uses Cosserat rod theory

Solved with a gradually extended integration domain

Provides higher shape prediction accuracy in confined spaces

Model accuracy is validated through finite element simulation and physical experiments.

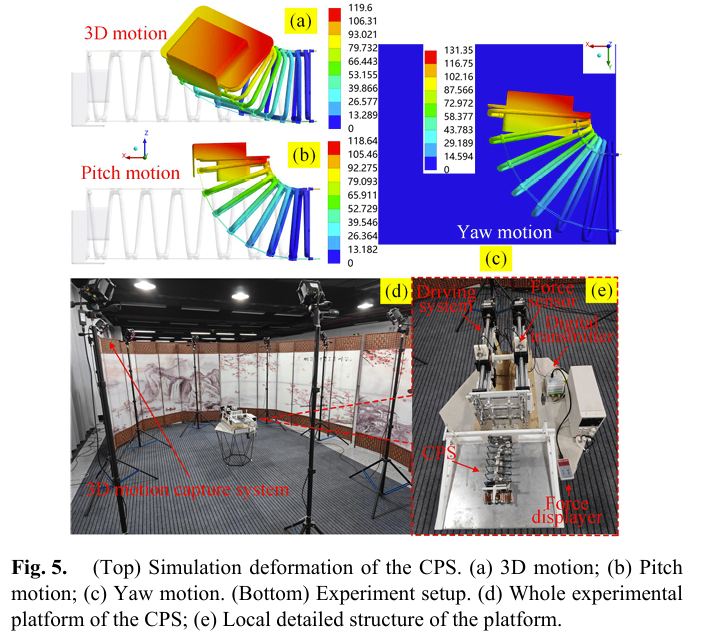

Spring backbone modeled as 3D solid elements

Driving cables modeled as tension-only elements

Simulations performed for pitching, yawing, and combined 3D deformation

A physical experimental platform integrates:

Cable-driven actuation system

Force sensors

NOKOV 3D motion capture system

Reflective markers are placed along the spring backbone to capture real-time three-dimensional coordinates. This enables reconstruction of the backbone centerline shape and posture angles under different actuation conditions.

Both the discrete and continuous models show good agreement with experimental measurements.

Model Type | Accuracy | Computational Cost | Typical Use Case |

Discrete Model (DM) | Good | Low | Real-time control, open environments |

Continuous Model (CM) | Higher | Moderate | Confined spaces, precise shape prediction |

FEA Model | Reference-level | High | Structural analysis and optimization |

Measured backbone deformation data obtained by NOKOV motion capture serve as the experimental benchmark for quantitative comparison.

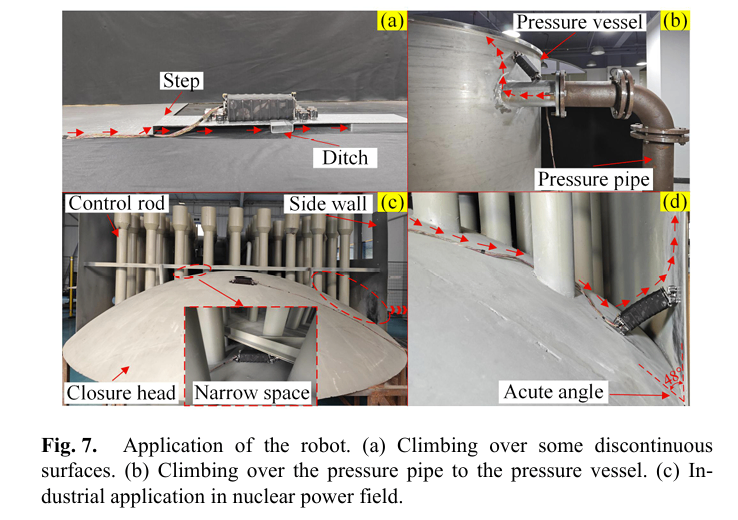

The robot is tested in nuclear inspection–related scenarios, including:

Crawling across discontinuous surfaces

Transitioning between pipelines and pressure vessels

Motion along complex equipment geometries

These demonstrations verify the robot’s ability to maintain stable motion and adaptability in environments representative of nuclear facility inspection tasks.

The NOKOV 3D motion capture system provides:

High-precision 3D position data of the backbone

Accurate reconstruction of continuous deformation

Reliable experimental reference for model validation

NOKOV motion capture enables objective, quantitative evaluation of continuum robot modeling methods and supports the verification of complex deformation behaviors that are difficult to measure using traditional sensors.

Learn more about NOKOV motion capture systems for continuum robots

https://en.nokov.com/resources/motion-capture-showcases/continuum-robot.html

NOKOV applications for inspection robots

NOKOV Applications for Inspection Robots

Q1: What makes the backbone different from traditional continuum robots?

The backbone is a retractable prismatic spring with a non-circular cross-section, allowing axial extension and anisotropic bending.The robot is inspired by earthworm-like locomotion, using continuous body deformation to move through confined and irregular environments.

Q2: What role does NOKOV play in this study?

NOKOV motion capture supplies the experimental reference data used to validate modeling accuracy and deformation prediction.

P. Yang, J. Zang, G. Jin, J. Long, B. Huang and J. Zhao, "Kinetostatic Modeling of Retractable and Prismatic Spring Body for Continuum Climbing Robots in Discontinuous Terrains," in IEEE Robotics and Automation Letters, vol. 9, no. 12, pp. 10954-10961, Dec. 2024